Give your customers the full benefit of the active materials in your battery, through substantially less resistance in the weld, while reducing your manufacturing costs through the use of Tiegel Automatic Extrusion-Fusion Line.

By using less lead in the small parts, and no epoxy because of the heat sealing, your material costs can also be dramatically reduced, leading to increased profits.

One of the features of this line is that it has been planned using our extrusion-fusion weld connection process, which has the following benefits:

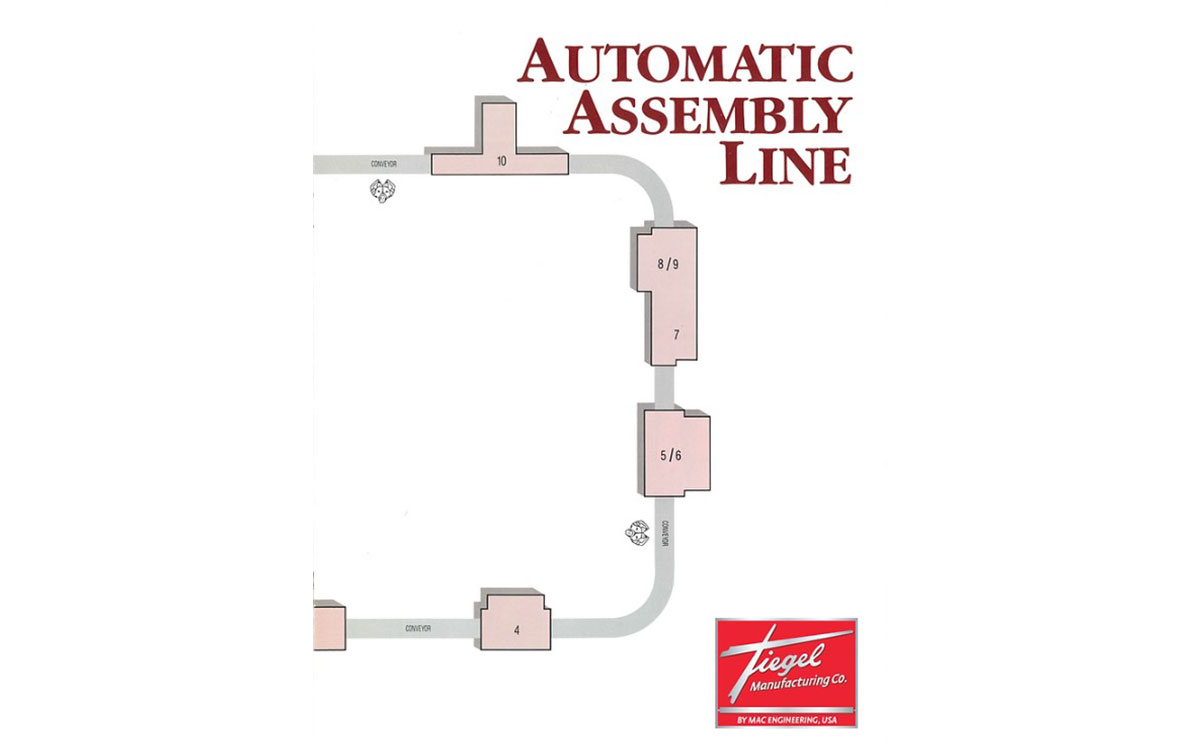

Need more info on the Tiegel Automotive Automatic Assembly Line for your engineering team?

Download our machine overview for more details.